What is a PTC Surface Heater?

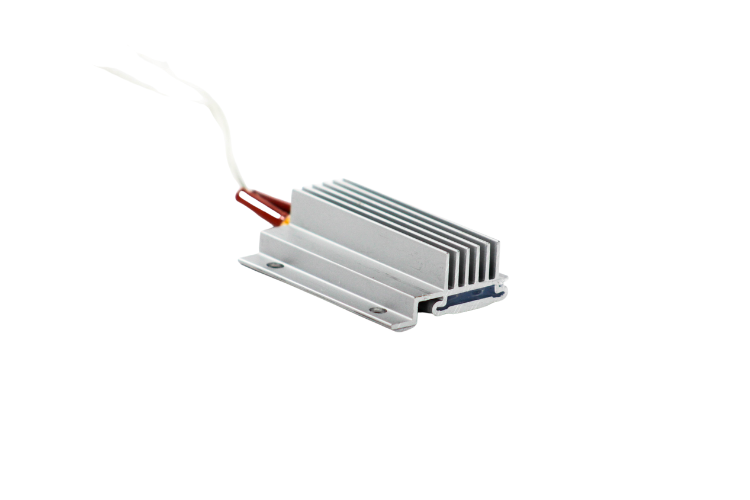

PTC surface heaters are enclosed in flat aluminum profiles designed to transfer their heat to an adjoining surface. These dynamic PTC heating elements combine the functions of heating and temperature control in one element. The HP Series heating profiles are embedded in an aluminum housing providing a strong design and excellent heat transfer characteristics. Each come prewired and predrilled for easy installation.

What’s the advantage of PTC Surface Heaters over other heaters?

PTC Surface Heaters are provided in flat aluminum profiles for contact heating with excellent heat transfer and high power density. The safety and dependability of the flat surface and the compact size offers the best option for design engineers.

Durability, reduced repairs, and downtime: PTC Heating Elements are much more durable than typical resistive elements greatly improving the durability and dependability of the components. There is no chance of burned out elements or coils with ceramic heaters.

Easy installation: The ready-to-use heating element can be fixed in any place by corresponding fixing holes on the profiles (e.g. drilled or punched mounting holes).

What is a PTC Cartridge Heater?

PTC Cartridge Heaters are dynamic heating elements that combine the functions of heating and temperature control in one element. Cartridge heaters are used when the heat needs to be transferred directly to a material, e.g. inside a container or vessel. They are inserted through the wall of the vessel or into a hole to reach the material to be heated. PTC Cartridge Heaters come in different power and voltage versions, and in various designs in terms of sheath material and shape.

What’s the advantage of PTC Cartridge Heaters over other heaters?

PTC Cartridge Heaters can be inserted into the body or material to be heated. The sheath material expands for tight-fit contact heating with excellent heat transfer and high power density. The safety and dependability of the flat surface and the compact size offers the best option for design engineers.

Durability, reduced repairs, and downtime: PTC Cartridge Elements are much more durable than typical resistive elements greatly improving the durability and dependability of the components. There is no chance of burned out elements or coils with ceramic heaters.

What is the difference between a PTC Contact Heating Element and a PTC Cartridge Heater?

In PTC Contact Heaters, the PTC ceramic is press-fitted into an aluminum profile for optimal power output. In PTC Cartridge Heaters, the PTC ceramic is enclosed in a silicone or aluminum jacket which allows for smaller and circular designs.

What is the surface temperature of a PTC Contact Heating Element?

The maximum surface temperature of PTC Heating Elements can be specified within a range of approx. 140°F to max. 464°F.

Is it possible to operate PTC Heating Elements / PTC Cartridge Heaters without an additional temperature fuse?

Yes. Due to the PTC effect, the heating element limits itself to the specified temperature, there is no danger of overheating.

How can I keep my component at temperature using a PTC Heating Element without separate control?

With the correct design of the PTC heating element, the desired temperature in the application is achieved without additional control.

Can I operate a PTC Contact Heater at a wide voltage range and what are the consequences?

Yes, PTC heaters are multi-voltage capable and can be operated at 100 - 240 V with almost the same power. This is a great advantage over conventional heating elements.

Why is it not possible to calculate the exact power output of a PTC Contact Heating Element?

As PTC Heating Elements are dynamic heating elements, their performance strongly depends on the application conditions. The correct design of the heating element is crucial which is why our engineers always design a heater based on the input of the customer.

Which factors must be considered when connecting a PTC Contact Heater?

PTC heaters experience an increased inrush current for a few seconds each time they are switched on. We therefore recommend to use a time-delay fuse in order to protect the application.

What are typical applications of PTC Contact Heating Elements?

They can be used for all applications that require heating of components or housings with high efficiency but limited space. Due to their protection class II design, PTC contact heating elements are also suited for safety-relevant applications.

Some typical applications are: Solid bodies, Containers of fluids or other dry materials, Appliances in industrial or commercial applications, Medical devices, Cosmetic equipment. and many more.

What are typical applications of PTC Cartridge Heaters?

PTC Cartridge Heaters are used for very low power and low temperature applications. Their high flexibility in shape makes them suitable for most difficult space conditions.

Some typical applications are: Oil Preheating, Fuel Pumps, Electric Car Charging Stations, Laminating Equipment, Glue Guns, Viscous fluid (heavy oil) Pumping Valves, 3D Printing Equipment, and many more.